Product features

- Also capable of mixing small quatities

- Easily accessible concentrate hopper

- Efficient - even with fat and molasses

- Suitable for placing on load cells

- Sturdy construction with gear motor drive

- High mixing accuracy - also in moist materials

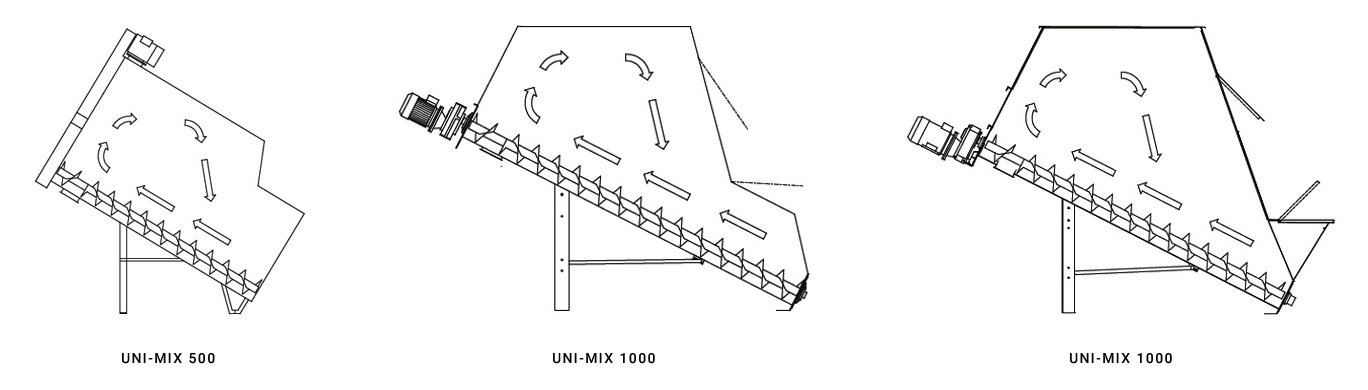

Mixing efficiency

The diagonal mixer is suitable for accurate mixing of almost any kind of raw material in the form of meal or granulate. It is possible to add liquid raw material such as fat, molasses or oil during the mixing process.

The mixing principle based on a large, slowly rotating bottom auger is gentle to the structure of the raw material which makes the diagonal mixer suitable for mixing of feed for cattle containing crushed material. Mixing of CCM is possible.

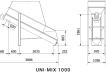

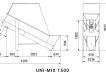

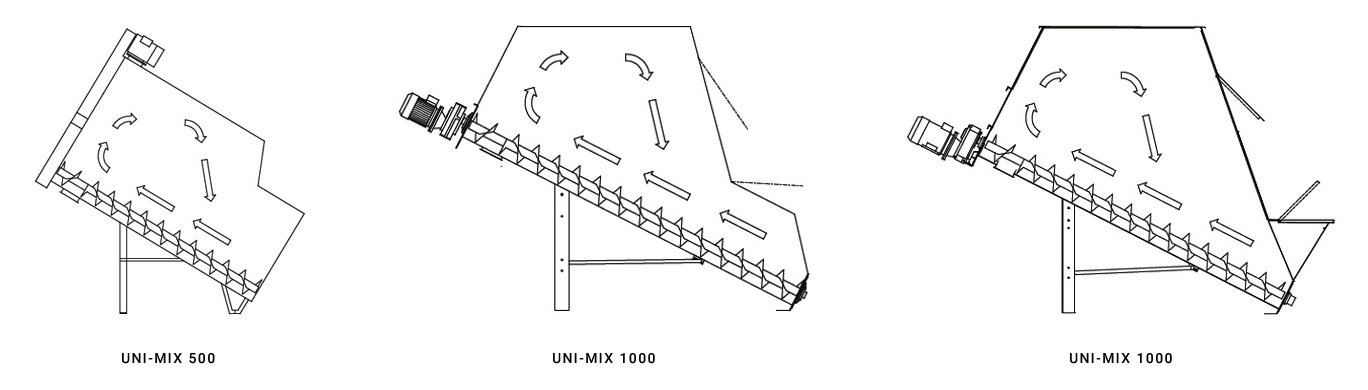

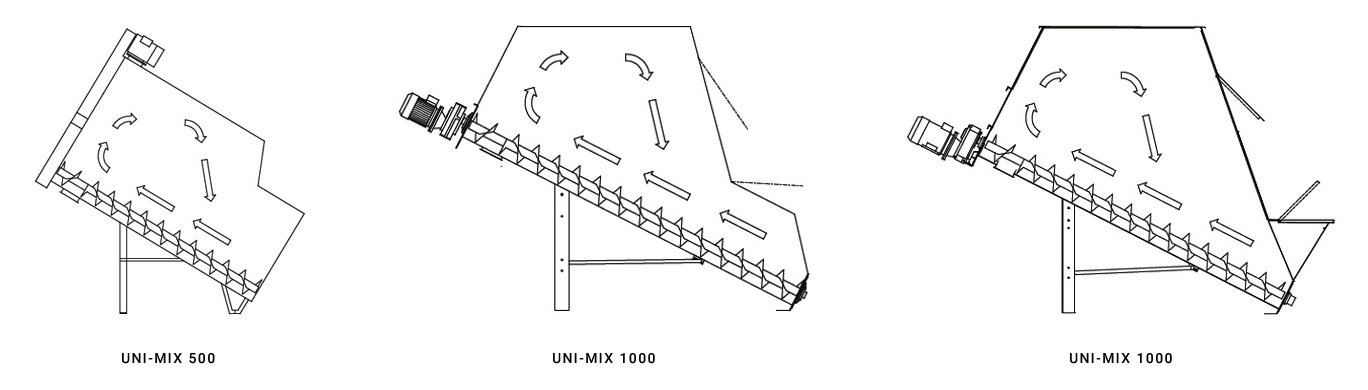

3 models

Technical specifications

| UNI-MIX 500 | UNI-MIX 1000 | UNI-MIX 1500 | |

|---|---|---|---|

| Mixing capacity (t/h) | 1 | 3 | 4,5 |

| Batch size (dry ingredients, kg) | 500 | 1000 | 1500 |

| Emptying time (minutes) | 6-8 | 8-10 | 10-12 |

| Mixing time (dry ingredients, minutes) | 10-15 | 10-15 | 10-15 |

| Mixing time (liquid ingredients < 3%,minutes) | 15-20 | 15-20 | 15-20 |

| Mixing accuracy | 1:10.000 | 1:100.000 | 1:100.000 |

| Motor size (kW) | 2,2 | 4 | 5,5 |

| Weight empty mixer (kg) | 230 | 440 | 465 |

| Liquid max. | 4% | 6% | 6% |

| Mixer angle | 30° | 27° | 27° |

| Transmission | Belt, chain drive | Gear motor | Gear motor |