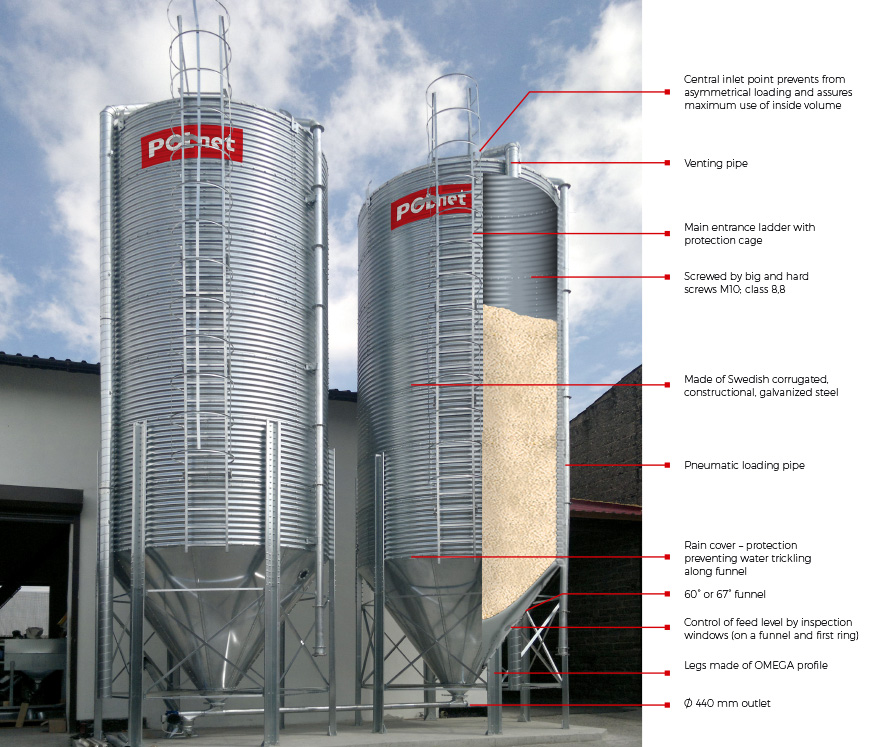

Feed silos

Silos can be seen on nearly all breeding and agricultural farms. They are used by large, as well as medium sized enterprises. Silos can be used to easily and quickly unload contents. They also serve the purpose of storing various loose materials.

The offer of the Polnet company includes feed silos of the highest quality. Wee encourage you to become acquainted with our products. They will certainly meet the needs of your farm.

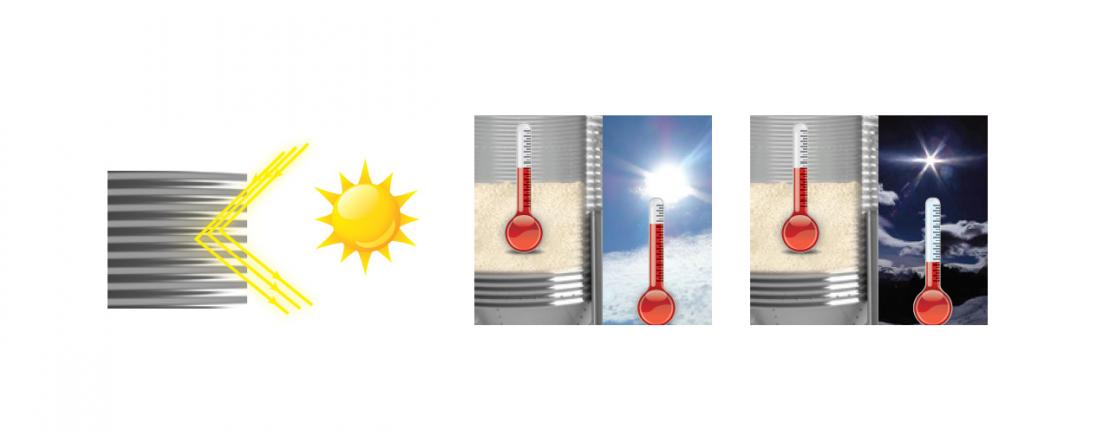

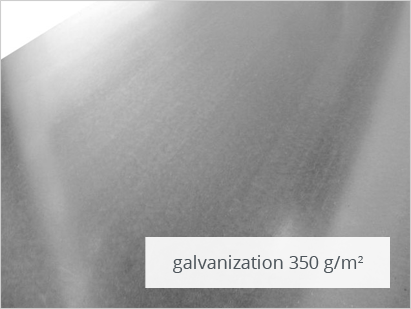

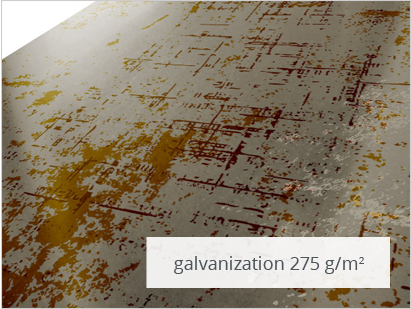

COMPARING COATINGS AFTER 6 YEARS OF USE

Large size selection

Silos can be ordered in five sizes. They are designed in consideration of smaller and larger farms, which need more capacious containers. The diameters of feed silos are:

- 1,8 m

- 2,1 m

- 2,5 m

- 2,8 m

- 3,5 m

The diameter corresponds to the capability of storing loose materials. After selecting a specific size, one can specify the capacity of the silo. Every container model has from 3 to 7 versions, which determine their capacity and total weight of the silos. The smallest product holds 2,7 t of feed, while the largest up to 48 t. There are as many as 25 possible combinations available. That way, a feed silo can be chosen exactly in accordance with one’s requirements.

The bottom funnel is angled at 60° and has a diameter of 440 mm. It is adapted to connect to all types of spiral, screw and chain-wheel conveyors.

Highest quality materials

In the production of our silos we use high-grade S350GD corrugated sheet metal. It provides increased structural durability and easy assembly. Precision in detail manufacturing is also important to quick create of the construction at the destination place.

Feed silos are also resistant to corrosion. Thus, they maintain proper hygiene of the materials stored within. Corrugated sheet metal affects the maintenance of a stable temperature regardless of the conditions, which prevents spoiling the feed.

In order to ensure long-term exploitation, we have decided to zinc plate the steel to a higher degree than compared to competitive solutions. Zinc plating at a level of 350 g/m² is a guarantee of the same sheet metal quality and appearance even after 6 years of intense usage. This time may be significantly extended, if the silo is used and maintained properly.

It is worth noting the exceptional resistance of feed containers to mechanical damage. Impact, abrasion and other accidental damage does not affect the structure. This ensures safe silo usage without having to worry about structural degradation.

Top quality silos

The effective functioning and continuous improvement of the quality management system at POLNET is confirmed by the ISO 9001: 2015 certificate. The scope of certification covers all POLNET activities related to the design and production of devices for receiving, transporting, drying, cleaning, storing grain and other loose products. The ISO 9001 certificate is a guarantee that POLNET provides services and produces the highest quality products, aiming not only to satisfy the customer, but also to constantly improve the products.

All Polnet feed silos meet the EN 1090 standard, which defines the criteria for the production of steel and aluminum structures. They also meet the requirements of Eurocode 3 - EU standards for structural safety of steel structures.

Each silo we make meets all the current EU regulations. As a leading manufacturer of silos, we are able to offer very attractive prices while maintaining rigorous quality standards. Detailed information on the offered silos can be obtained by downloading the catalog available on the website www.

If you have any questions related to the date of implementation or the available offer, please contact us by phone or e-mail. We are happy to advise you and help you choose the optimal solution. We will also provide you with a whole range of necessary information on the operation and maintenance of our silos so that they will serve you reliably as long as possible.

Additional equipment on demand

The standard silo equipment includes:

- pneumatic filling sets,

- omega profile legs,

- ladders with safety hoops,

- inspection windows,

- feed truck connector.

We are, however, able to expand the functionality of containers with additional options, such as: side unloading chute, manual slider hatch and set under the silo responsible for user comfort and adaptation to the farm’s needs. For additional silo protection, it is worthwhile to equip it with a rain cover, while a strain gauge humidification system will enable better control of the conditions inside the silo.

Additionally, we also offer:

- inspection hatches,

- vibrators,

- rocker based system for opening the silo’s upper hatch from the ground.

We also provide containers with bottom funnels at an angle of 67°.

We encourage you to contact us via telephone or e-mail. We will gladly answer any questions regarding price quotations and performance times, as well as any other issues which may interest you. We also offer professional consulting and an efficiently functioning service.