Storage and transportation

from 2 to 6 t, ø1.8m

Product description

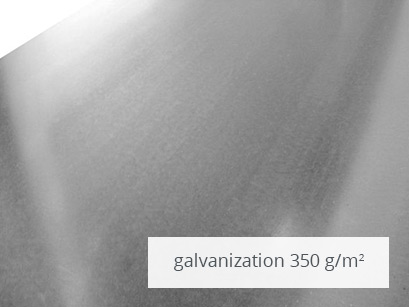

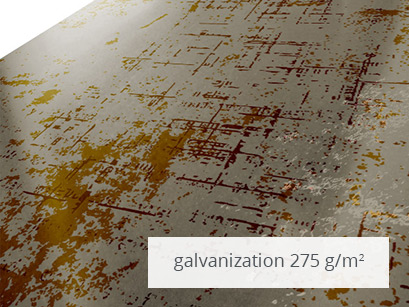

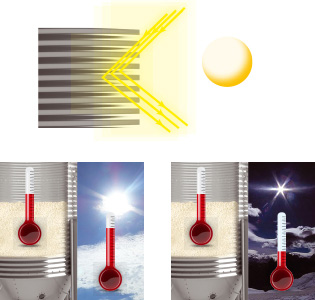

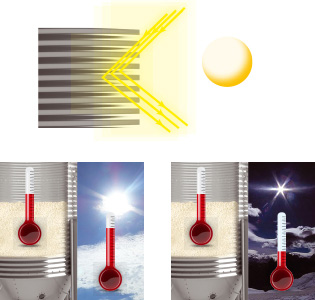

HE USE OF HIGH-QUALITY CORRUGATED SHEET ASSURES THE FOLLOWING:

- increased structure resistance

- resistance to corrosion

- stable temperature of fodder inside the silo in any condition

- easy and simple assembly thanks to precise manufacture of all workpieces

- modern profiling technology

Technical data

| Model | Diameter [m] A | Vol. [m3] | Fodder vol. [t]* | No of legs | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|---|---|---|

| 180-1 | 1.8 | 4,2 | 2,8 | 4 | 478 | 902 | 1237 | 750 | 3367 | 4030 |

| 180-2 | 1.8 | 6,6 | 4,4 | 4 | 478 | 902 | 1237 | 750 | 4269 | 4932 |

| 180-3 | 1.8 | 9,0 | 6,0 | 4 | 478 | 902 | 1237 | 750 | 5171 | 5834 |

* conversion factor for fodder: 0.65 t/m3

The Producer reserves the right to make changes in the construction and parameters of the equipment on offer, relative to the range presented on the website and catalogs.

- Feed silo is designed only for storage of feed in maximum density of up to 650kg/m3

- Feed silo should be positioned and leveled so that all its legs have the same level of seating on foundation in relation to one reference point, with tolerance +/- 2mm

- The legs of mounted silo should be precisely vertical and must be positioned in a polygon with equal sides and diagonals

- The feed silo outlet after filling is reduced.The device mounted under the funnel (between funnel and the ground) cannot tightly fit in the space, but should have telescopic connections with minimum1 cm-pitch

- Feed silos in standard version are designed to be mounted on strain gauges with a thick and rigid upper clamping plate

- Feed silos in standard version are not designed to be mounted on spedition and bunker constructions, since their construction is not adjusted to dynamic, gravity unloading

- Feed silos in standard version are designed for moderate climate zone with wind 30m/s and snow 1,2 kN

- Feed silos are adjusted to be mounted by lifting the assembled silo to vertical position, but only in case of using additional wood reinforcements or metal reinforcements of legs, described in Assembly Manual

Accessories

3 TYPES OF LOADING:

PNEUMATIC FILLING SET

PNEUMATIC FILLING SET PNEUMATIC LOADING

PNEUMATIC LOADING MECH/PNEU LOADING

MECH/PNEU LOADING

FULL OPEN HATCH

FULL OPEN HATCH MAIN ENTRANCE LADDER WITH PROTECTION CAGE (SHORT GROUND LADDER AVAILABLE AS OPTION)

MAIN ENTRANCE LADDER WITH PROTECTION CAGE (SHORT GROUND LADDER AVAILABLE AS OPTION) 2 INSPECTION WINDOWS: ON FUNNEL i ON FIRST RING

2 INSPECTION WINDOWS: ON FUNNEL i ON FIRST RING OMEGA PROFILE LEGS

OMEGA PROFILE LEGS FEED TRUCK CONNECTION

FEED TRUCK CONNECTION RAIN COVER

RAIN COVER SIDE OUTLET

SIDE OUTLET SHORT GROUND HOOK-IN LADDER

SHORT GROUND HOOK-IN LADDER INSPECTION HATCH

INSPECTION HATCH UNLOADING SET UNDER A SILO

UNLOADING SET UNDER A SILO HAND LATCH

HAND LATCH FUNNEL FLOW

FUNNEL FLOW TENSOMETRIC MOISTENING UNIT

TENSOMETRIC MOISTENING UNIT Vibrator

Vibrator

IN THE KIT:

SILO CONNECTION

SILO CONNECTION TRANSITION SET WITH SHUTTER

TRANSITION SET WITH SHUTTER SINGLE SILO UNLOADER

SINGLE SILO UNLOADER DOUBLE SILO UNLOADER

DOUBLE SILO UNLOADER SHAFT FOR SILO UNLOADER

SHAFT FOR SILO UNLOADER