Cutting

Laser cutting is modern, quick and one of the most precise currently used technologies of sheet cutting.

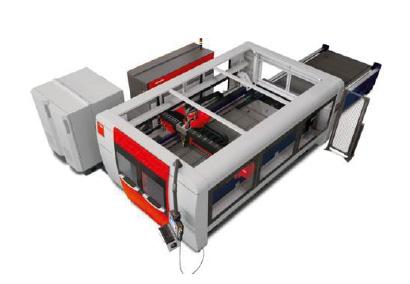

We offer the complex services in range of laser cutting with use of modern machines from Swiss company BYSTRONIC and Amada

Amada ENSIS-3015 AJ

BySprint Pro 3015 / 4020

WE ASSURE:

- 100% repeatability;

- Any shapes of cut elements;

- Perfect quality of edges and surfaces;

- Optimum material consumption;

- We are able to realize various types of elements with use of laser technology, upon the basis of supplied models, technical drawings or CAD/CAM documentation.

We also offer services for long-run cutting with a tape cutter from company PEGAS-GONDA type 290 × 290 X-CNC-1500-F with a total power of 2.2 kW:

| TECHNICAL POSSIBILITIES IN THE FIELD OF CUTTING SERVICE: | |

|---|---|

| pipes | up to Ø 290 mm for 45° |

| profile 90° | 320 mm × 290 mm |

| profile 45° | 240 mm × 150 mm |

| square profiles | up to 290mm |

| round bars | up to Ø 180 mm |

| square bars | up to 180 mm |

This year, our machinery will also be expanded with an ANKOVO machine.

We ENSURE with high quality of cut pieces with perfect quality of edges and surfaces with the optimal use of raw material.

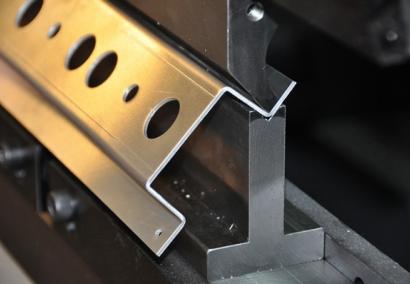

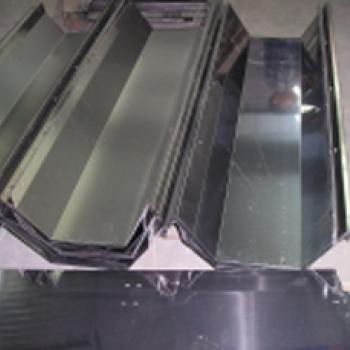

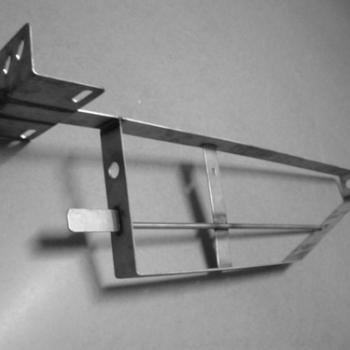

Bending

In order to meet the expectations of our customers we offer the services of quick and precise bending, curving and straightening operations of various materials, using the advanced, CNC-controlled bending brake AFM EP 31-160 from the Swiss company Bystronic, AMADA HFE M2 5020 and AMADA HFE M2 2204.

Our device ensures perfect precision and accuracy of bending.

| BYSTRONIC TECHNICAL DATA | |

|---|---|

| Maximum pressure | 160 tons |

| Maximum bending width | 3150 mm |

| Maximum thickness of materials: | structural steel: 0,5-15 mm stailess steel: 0,5-12 mm aluminium: 0,5-25 mm |

| bending brake AMADA HFE M2 5020 |

sheet metal bending up to 4000 mm in length |

| bending brake AMADA HFE M2 2204 |

sheet metal bending up to 2000 mm in length |

At the customer's request, we make any number of copies while maintaining 100% repeatability of shapes.

With constant cooperation, we are able to adapt the device to Your needs.

We guarantee high-quality elements with any number of repeatable elements. We are characterized by experience, fast order fulfillment and competitive prices.

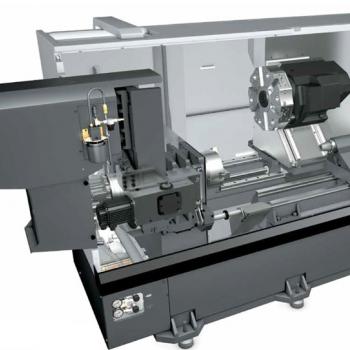

Turning

We can produce details according to received technical drawings, or all necessary documentation can be prepared by our highly qualified designers, on the basis of received samples or instructions.

Thanks to modern lathe CNC HAAS ST 20 we can guarantee highest quality and precision of our production. We can achieve dimensional repeatability, what assures functionality of final product We draw both on proven solutions and the latest technical innovations.

| TECHNICAL DATA: | |

| diameter of turning bars | Ø 50 |

| maximum diameter of machining | 280 mm |

| maximum lenght of machining without mounting | 533 mm |

| conventional | CORMAK C6256X1500 |

| roll length | 1500 mm |

| above the support | 320 mm |

| over the bed | 560 mm |

| max | 625 mm |

Welding

Our welding procedures are performer in accordance with PN-EN ISO 3834-2.

We offer the services in the field of welding fromcarbon and acid-resistant steel with use of automatic welding station by using TIG, MIG / MAG methods.

We provides welding services of elements made of steel:

- carbon steel

- stainless steel

We have welding stations equipped with modern welding automatic machines MIG / MAG from KEMPPI, REHM companies, impurities removing system ERGO-STW and welding robot from company OTC-Daihen, type OTC AII V6L, which allows to weld the details with maximum width 1400 mm and length 2500 mm.

With use of modern weldingmachines we assure high quality and short realization times in reasonable price.